Hess Objectives

Hess Objectives

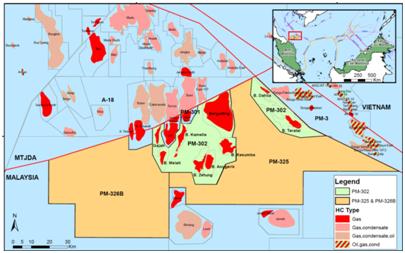

NMB Project Background

NMB Project Background

The Full Field Development (FFD) phase 1 includes:

| In Field Flowlines | Length (km) |

Outside Diameter (inch) |

Grade |

|---|---|---|---|

| Bergading-C remote WHP to BergadingCPP | 4.5 | 12 | API 5LX65 Non Sour |

| Bergading-D remote WHP to BergadingCPP | 7 | 12 | API 5LX65 Non Sour |

| B.Kesumba remote WHP to BergadingCPP | 20 | 16 | API 5LX65

Non Sour |

| Dry Gas Export Pipeline | Length (km) |

Outside Diameter (inch) |

Grade |

|---|---|---|---|

| BergadingCPP to ENGDS/EVA subsea wye tie-in | 19 | 24 | API 5LX65(with NACE requirements) Sour |

| Condensate Export Pipeline | Length (km) |

Outside Diameter (inch) |

Grade |

|---|---|---|---|

| BergadingCPP to BergadingFSO | 2 | 6 | API 5LX65 Non Sour |

Services By JPAC technologies Pvt. Ltd.